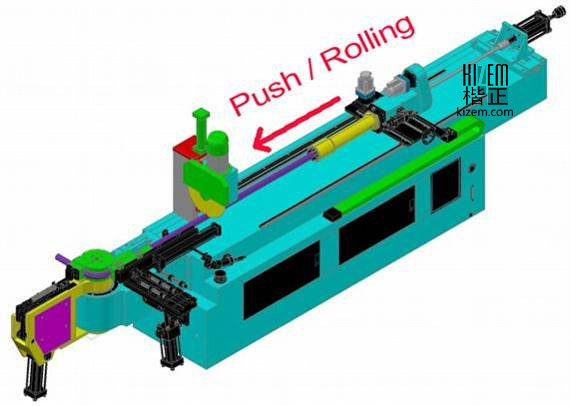

← Push / Rolling Pipe: Automatic by Electric ( servo motor )

← Push / Rolling Pipe: Automatic by Electric ( servo motor )

Automatic changing stacks (betweenbending stack and pushing stack) by servo motor.

Features :

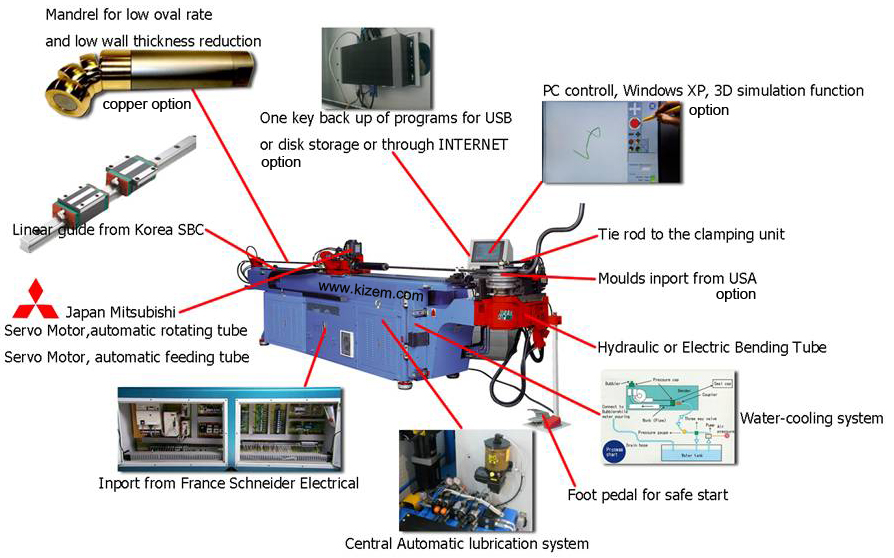

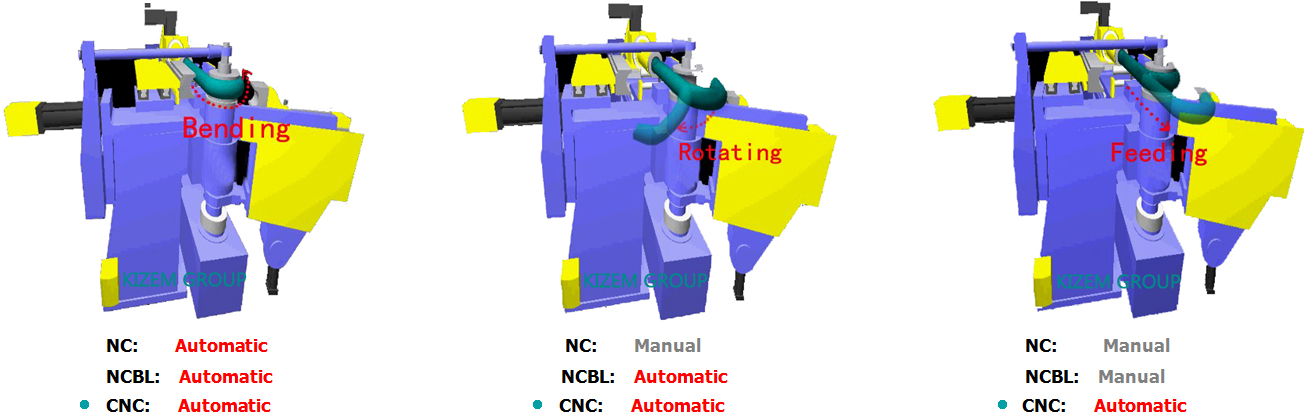

● Automatic bending tube by electric, rotating tube by electric, feeding and pushing / rolling tube by electric. Fully automatic type.

● Automatic lubrication.

● 3D suimulation as option.

● PLC controlling / Industry computer controlling, imported from Japan Mitsubishi.

● Touch screen operation panel, can input, store and display bending data and to controll the machine bending.

● Any language can be showed in the touch screen for easy to controlling.

● Anticipated mandrel retraction unit. It adops imported special control system. With high stability.

● With water-cool system. Air-cool / oil-cool system as option.

● The head of bending machine is "cast iron".

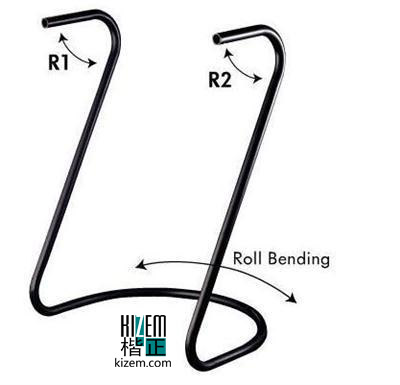

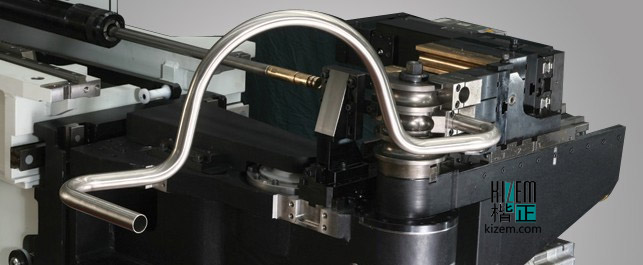

● Can bend round, square, rectangle, profile tube or rod.

● With / without mandrel bending.

● The tube or bar can be mild carbon steel, stainless steel, copper, aluminum and other material.

● The bending precision is ±0.1mm, controlled by encoder for sure the high precision.

● Foot pedal for safe start.

● CE, ISO9001 Certification.

● All technical imported from Germany.

Technical data :

Max bending capacity - Ø63×4 mm

Max pushing radius - +∞

Standard feeding length - 3000 mm

Max pushing degree - 360

Controller - PLC / Industry computer

Accuracy (Feeding & Rotating & Bending) - ±0.1